The author of this blog, Sharad, is an expert writer in the field of industrial technologies. He has done extensive research to bring the facts about Limit Switches used in industries to help out readers.

In this blog, we’ll explore Limit Switches in Industrial Automation and their role in modern control systems.

Limit switches are very important for the safety and automation of factories. These basic tools keep workers and machines safe by knowing when machines are in certain locations. They stop unsafe movements and make sure that all industrial plants throughout the world run smoothly.

What is a Limit Switch?

A limit switch is an electromechanical device that can tell if something is there or where it is by touching it. The switch changes its electrical state when something contacts the actuator. This action tells control systems to start, halt, or adjust how the machine works.

The principle of operation is simple. A force from outside touches the actuator arm or plunger. This movement makes electrical contacts inside work, which opens or closes circuits. The signal goes to control panels where operators keep an eye on the machinery.

You May Also Like Reading : Importance of Display Lists and Switch Lists in Industrial Operations

Different Kinds of Limit Switches

There are many limit switch types that are used in industrial automation for different things.

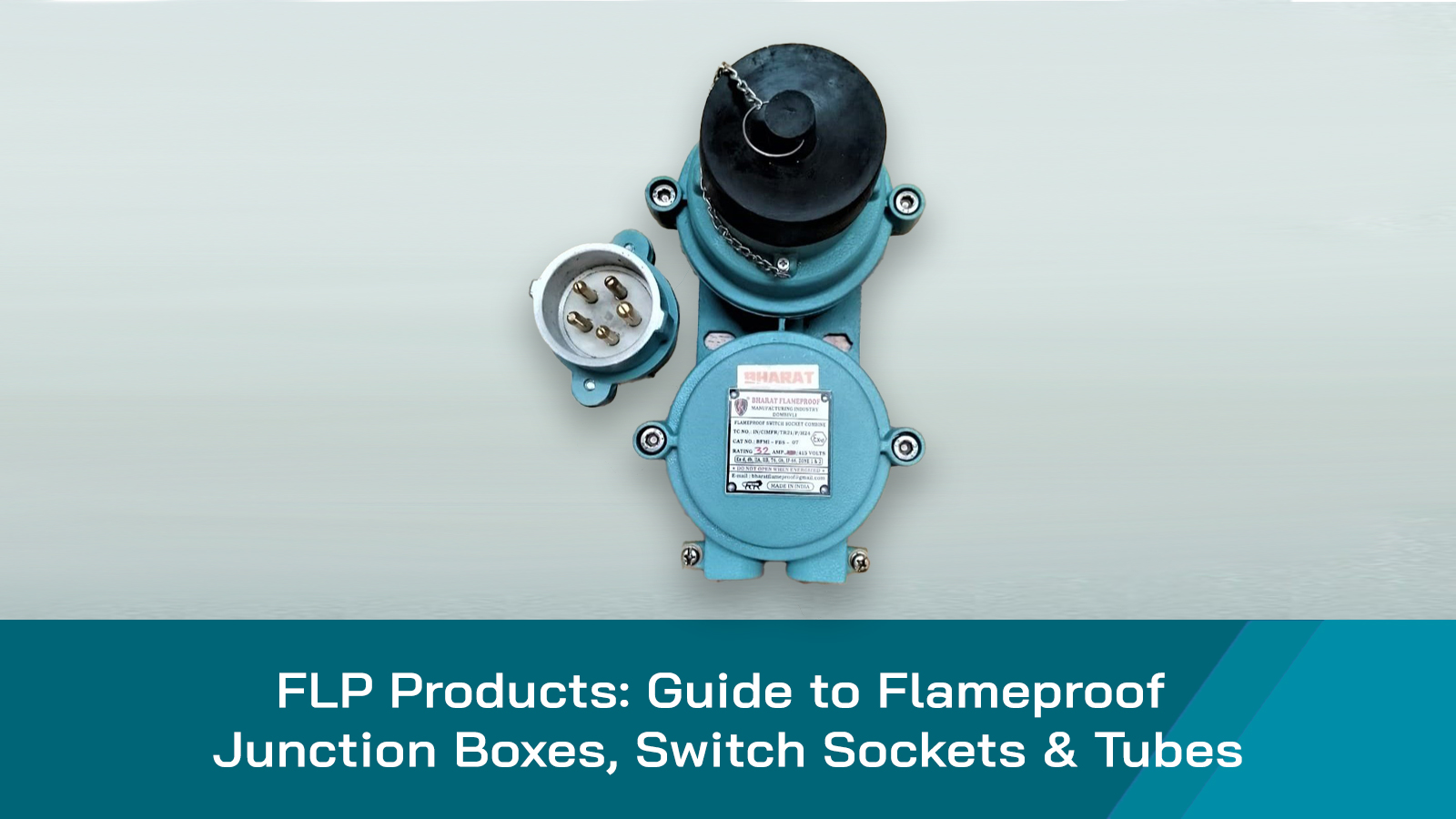

FLP Limit Switch

FLP rotary switch designs are built to last in tough conditions. These flame-proof switches keep dangerous regions from blowing up. They are built to last, with sealed housings that keep any sparks inside.

Micro Limit Switch

The micro switch limit switch is small and works well. These switches can move things quite accurately in small places. Micro limit switch designs let you switch things on and off with very little force.

Different Types of Door Switches

Door limit switch units keep an eye on safety obstacles and access points. Door switch systems make ensuring that protective coverings stay closed while the machine is running. Different door limit switch types work well with different installation needs.

No Touch Switch

Proximity detection without touching is what no-touch switch technology employs. These limit switch proximity type devices use electromagnetic fields to detect metal objects. They stop wear from repetitive contact operations.

Different Types of Actuators

Roller, lever, plunger, and whisker are all common forms of actuators. Each limit switch element meets certain mechanical needs, dependent on how the object moves.

Uses of Limit Switches

Door limit switch systems are very important for industrial doors. These switches let you know when the overhead doors are fully open or closed. Safety circuits stop doors from moving when workers go into off-limits areas.

Limit switches are used in manufacturing lines to find out where products are on conveyor belts. They count things that go by and set off sorting machines at the right times. For sealing and labelling to work, packaging equipment needs to be in the right place.

Robotic systems need a lot of switches to keep an eye on arm positions and stop crashes. There may be separate switches for each joint that set safe operating ranges.

Explore More: Top Industries That Benefit from Display Lists and Switch Lists in Operational Systems

Electromagnetic Lock & Limit Switch Integration

When you use electromagnetic locks and door switches together, you get full security solutions. Before the equipment can start, the door limit switch checks to see if the lock is engaged. This integration stops doors from being opened by accident when they are still open.

Both locking mechanisms and position sensors need to send positive feedback to safety circuits. Limit switch terminals offer dependable status signals that work with electromagnetic systems.

Basic Wiring and Connections

You need to know some basic electrical principles to connect a limit switch connection. Most switches have three terminals that can be set up in several ways.

Common terminal is where ordinarily open and typically closed contacts connect. The limit switch specification sheet has wiring schematics for each model that are correct.

The load circuit is linked to one terminal, and the power source is linked to the other. Electricity flows through the chosen contact line when the switch is on.

Limit switch terminals stay safe from water and dirt when they are installed properly. Sealed connectors stop corrosion that could break the connection.

Conclusion

Picking the correct limit switch is important for making sure that the technology works and workers are safe. Think about the weather, how much space you have, and the need to switch when you have to choose between different types. Selecting the quality Limit Switches ensures safer operations, smooth control responses, and greater efficiency in automated industrial environments. If these important safety devices are set up and taken care of correctly, they will work reliably for years in a factory.

FAQs

Micro switches, rotary switches, door switches, and proximity-type no touch switches are the most prevalent varieties. Each one is useful for certain tasks depending on how much space is needed and the weather.

Attach the power supply to the common terminal. Depending on your control logic needs, wire the load through either the normally open or normally closed contact. Always use the wiring diagram that came with your device.

FLP (flame-proof) switches feature cases that protect them from explosions and keep sparks within. They are safe to use in situations where there might be dust or fumes that can catch fire.

Use door switches whenever you need to make sure that barriers are in the right place. They’re necessary for interlocking systems that stop machines from working when protective covers are open.